feature copy

If there is one thing gun guys (and gals) will argue about, it is ammunition. In what ways, you ask? Caliber, bullet weight, design, manufacturer, velocity, you name it. They (ok, we) will argue about it.

How do you go about choosing the best-performing ammunition for your needs? Ideally, you will go out and test. Because doing your own testing, to standard, in your environment (altitude, temperature, humidity, equipment) is the best choice.

Unfortunately, not everyone can perform the correct testing to the national standards. Sometimes that is because of the lack of availability – of a range, of people to work it, of money to pay for it, and the quantity and variety of ammunition necessary.

There is good news, though. There are large organizations that can do the needed testing correctly. Some will share that information as openly as possible with other agencies.

FBI Testing and Data

In the aftermath of the 1986 Miami shootout against two determined suspects, the Federal Bureau of Investigation developed a protocol to test handgun ammunition for its viability as a “duty load.” That testing includes performance in calibrated ballistic gelatin. During the testing, the bullets are shot into both bare gelatin as well as through intermediate barriers and then into the gelatin. These barriers include heavy cloth, dual laminate auto glass, 20-gauge steel, wallboard, plywood, and automobile glass.

Barriers

The most current information I have describes the intermediate barriers in these ways:

– Heavy Clothing covers the gelatin block with one layer of a cotton t-shirt, a layer of cotton t-shirt material, a layer of Polartec 200 fleece, and finally, a single layer of denim. Originally, this test was four layers of denim.

– Two pieces of 20 gauge hot rolled steel are set three inches to simulate the thinnest part of a car door.

– To recreate an interior wall, two pieces of sheetrock (or gypsum) are set up three and a half inches apart.

– A three-quarter-inch thick piece of AA-grade plywood is used to recreate an interior door.

– Quarter-inch thick, laminated auto glass tests performance when shots are fired through the windshield. The shot is taken at a combined angle of 45 degrees up and 15 degrees off-center.

The gelatin block is set back eighteen inches in each steel, wallboard, plywood, and auto glass test.

There are set standards for the calibrated gelatin blocks in terms of performance for the testing to be considered valid. That is for another article.

Getting the data from someone else isn’t a bad thing. But what if you or your boss need to see it themselves? Do they want to witness the testing? You may not be able to get into the test facilities, but you might be able to catch a demonstration.

Ammunition Demonstrations

For many years, various reputable ammunition manufacturers have presented ammunition performance demonstrations for various law enforcement agencies. I was fortunate to go to a number of these over the years. My old organization hosted some, and we attended others.

Generally, the demonstration days followed this format – we started in a classroom. There would be a presentation on the FBI protocol and how their duty ammunition performed during it. Often, they would also discuss their rifle and shotgun ammunition.

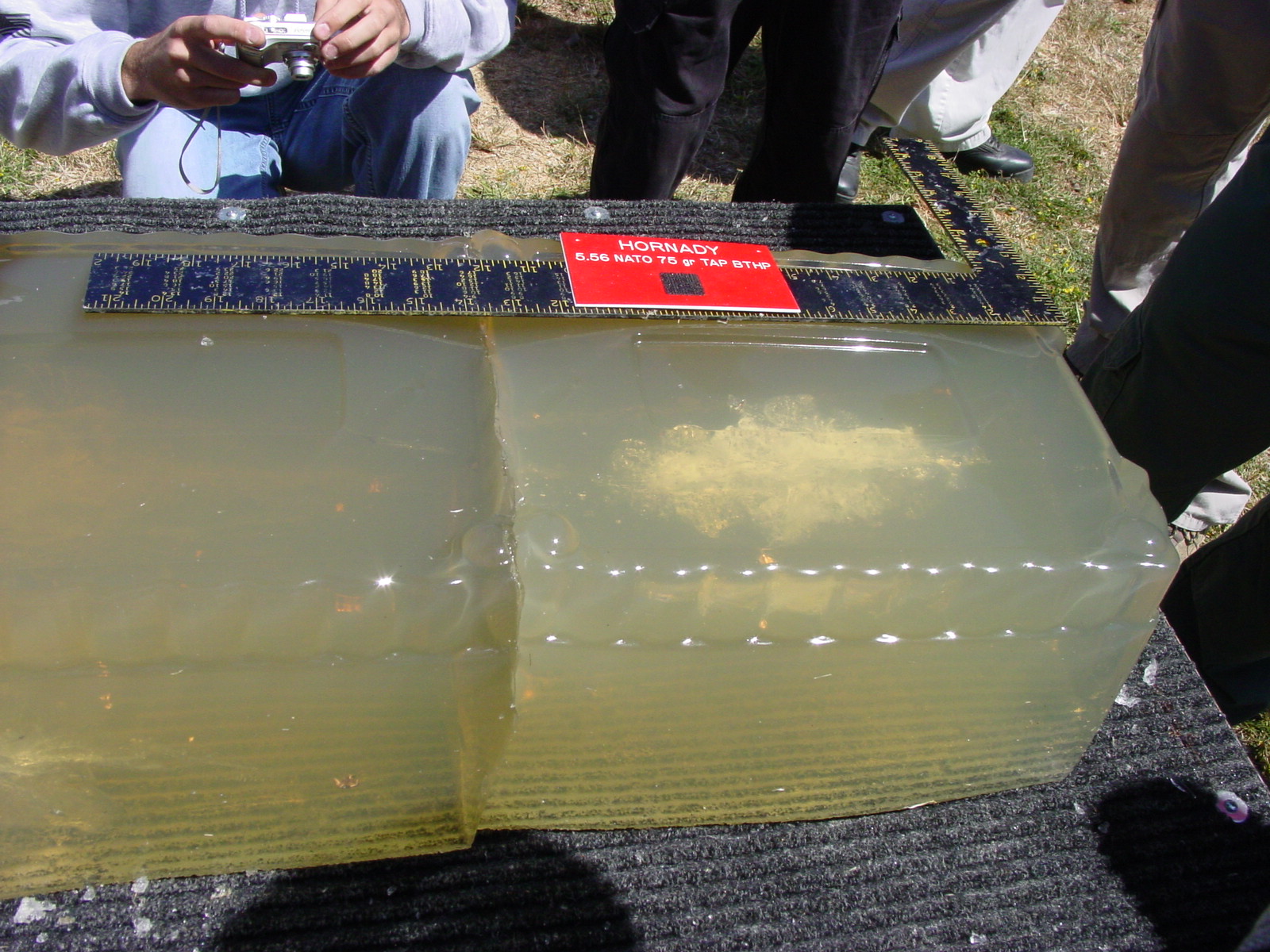

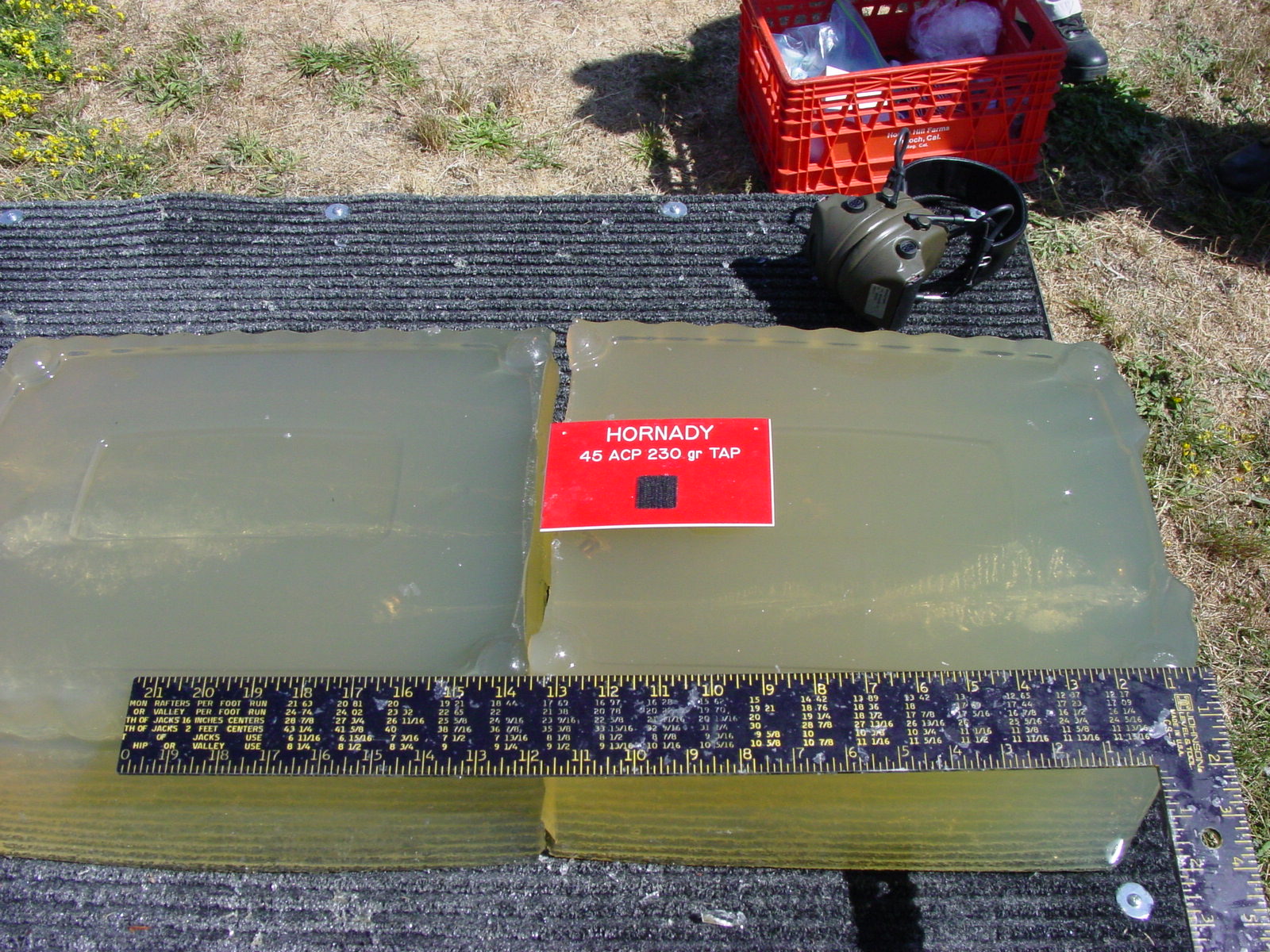

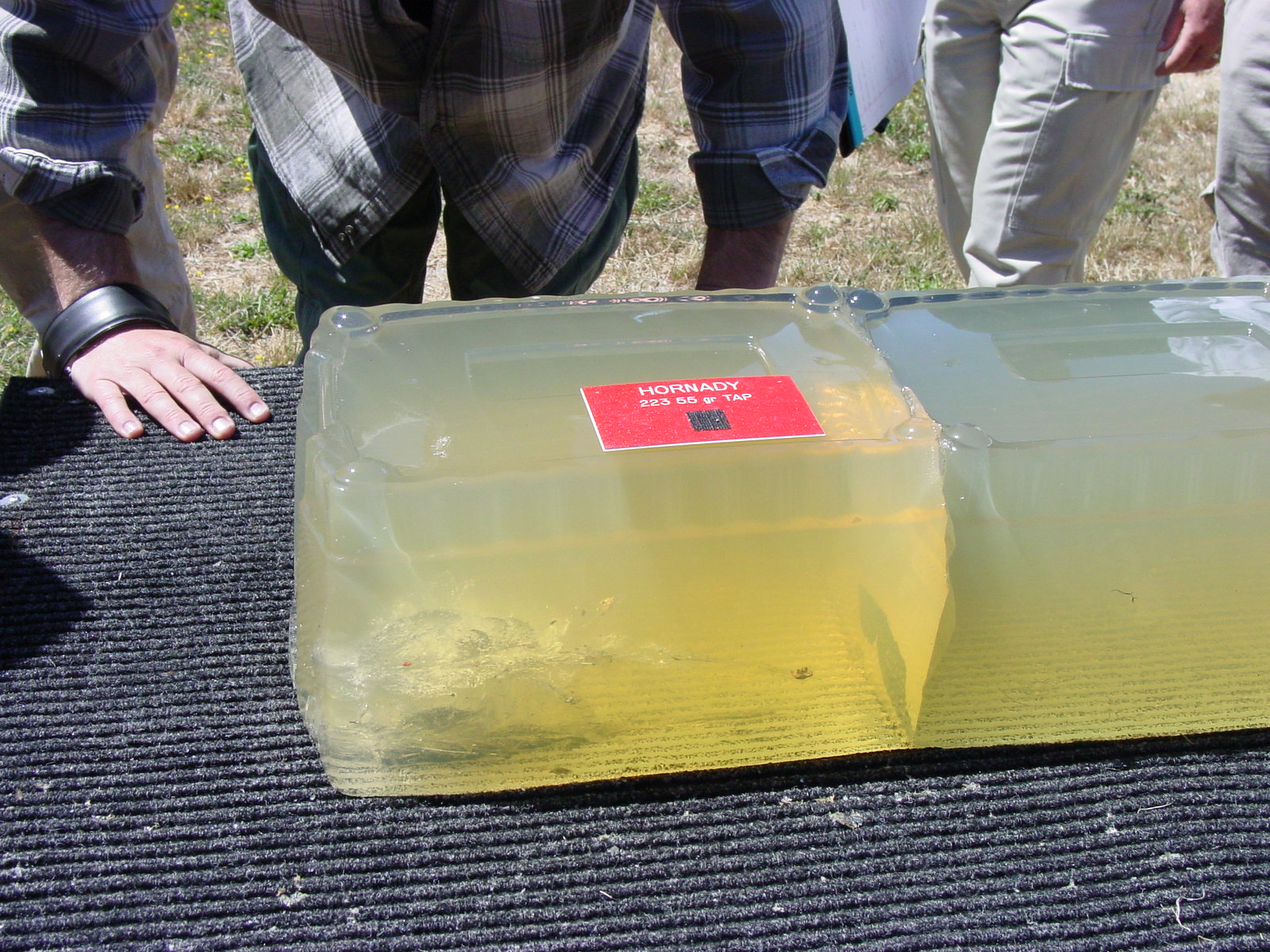

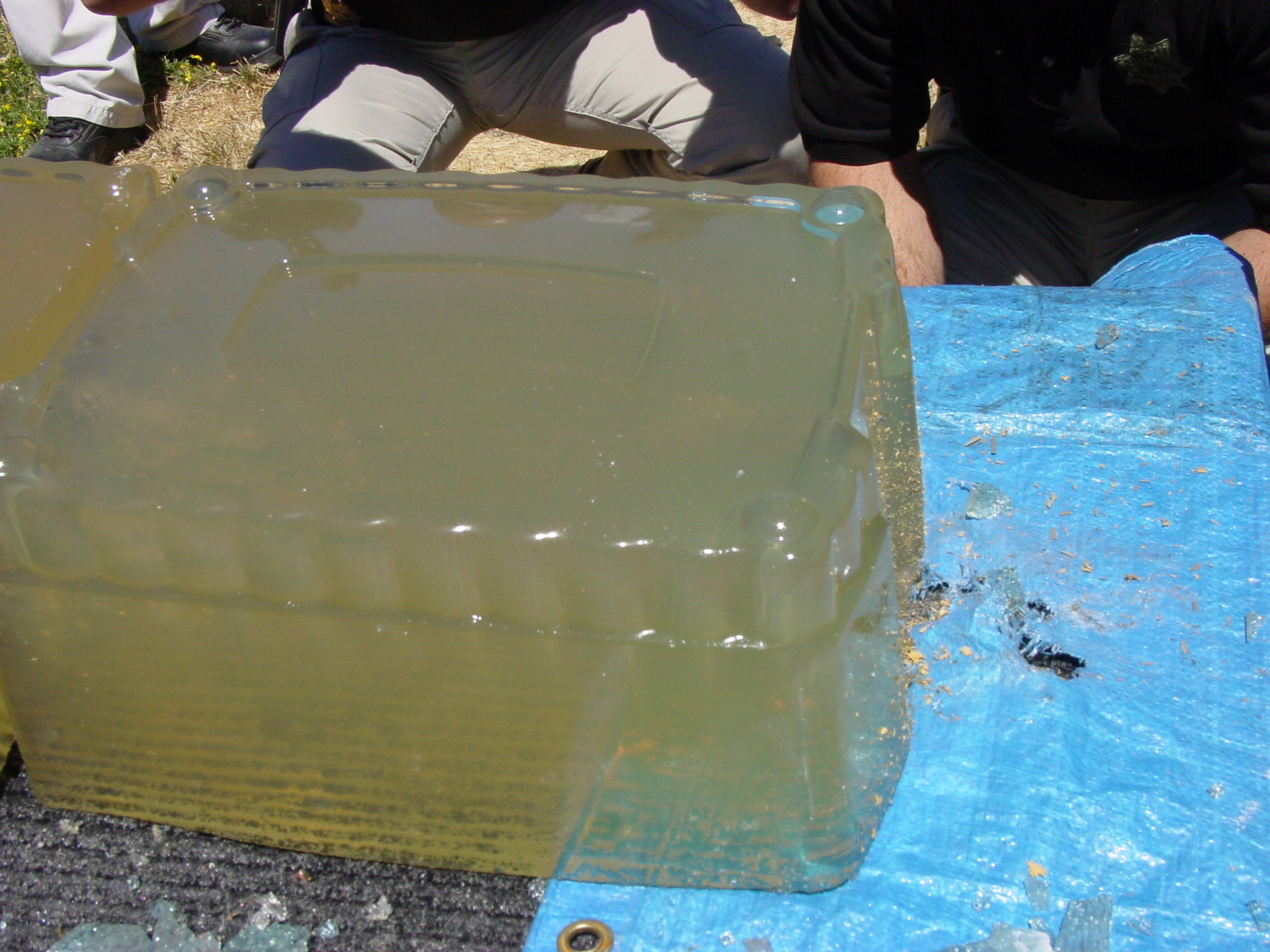

Then we go out to the range. The manufacturers’ representatives would bring out ballistic gelatin and set it up. The reputable companies would cover the calibration process and then demonstrate the calibration.

From there, they would shoot the gelatin with their offerings in various calibers. Sometimes, they had specific intermediate barrier items; other times, real-world items like residential doors and car bodies were used.

The reps would then allow attendees to shoot any duty ammunition they brought. This was so they could compare the performance and any differences between them. We were encouraged to take notes and plenty of photographs at every one I attended. And they handled the advertising and marketing sides with ballcaps and t-shirts.

When you attend one of these events, take every photo you can and document how all of the ammunition performed. It helps build your expertise.

I have mentioned reputable companies a couple of times in this piece. One of the most refreshing comments I heard at one of these was several years ago. A loading from another company outperformed one from the host business. That representative said, “theirs is better than ours, but we’re working on it,” I put that comment in my notes. To this day, I am a big fan of that company’s products.

At various times, ATK/Federal & Speer, Hornady, and Winchester have all offered ballistic demonstrations through their law enforcement divisions.

Where Can I Find It?

The part of the Bureau that deals with ammunition performance and other related equipment is the Ballistic Research Facility (BRF), currently located in Huntsville, Alabama. For law enforcement, the BRF is very responsive. When my old organization was considering a switch from .40S&W pistols to 9mms, I had several phone calls and email exchanges with the special agent in charge of the BRF.

The FBI’s data is available to police and sheriff’s departments with a written request signed by an administrator on letterhead. Your local FBI office should be able to provide you with the specifics.

While you are at it, if you have not shot at least one of your ballistic vests, now would be a good time.

The bottom line, when it comes to choosing your defensive ammunition, make your decisions based on the best information you can find.

RESOURCES:

Hornady’s L/E Line and FBI protocol

ATK/Federal and Speer L/E Line

(No Ratings Yet)

(No Ratings Yet)