y-feature_4803

Working cops now have a new standard for their body armor.

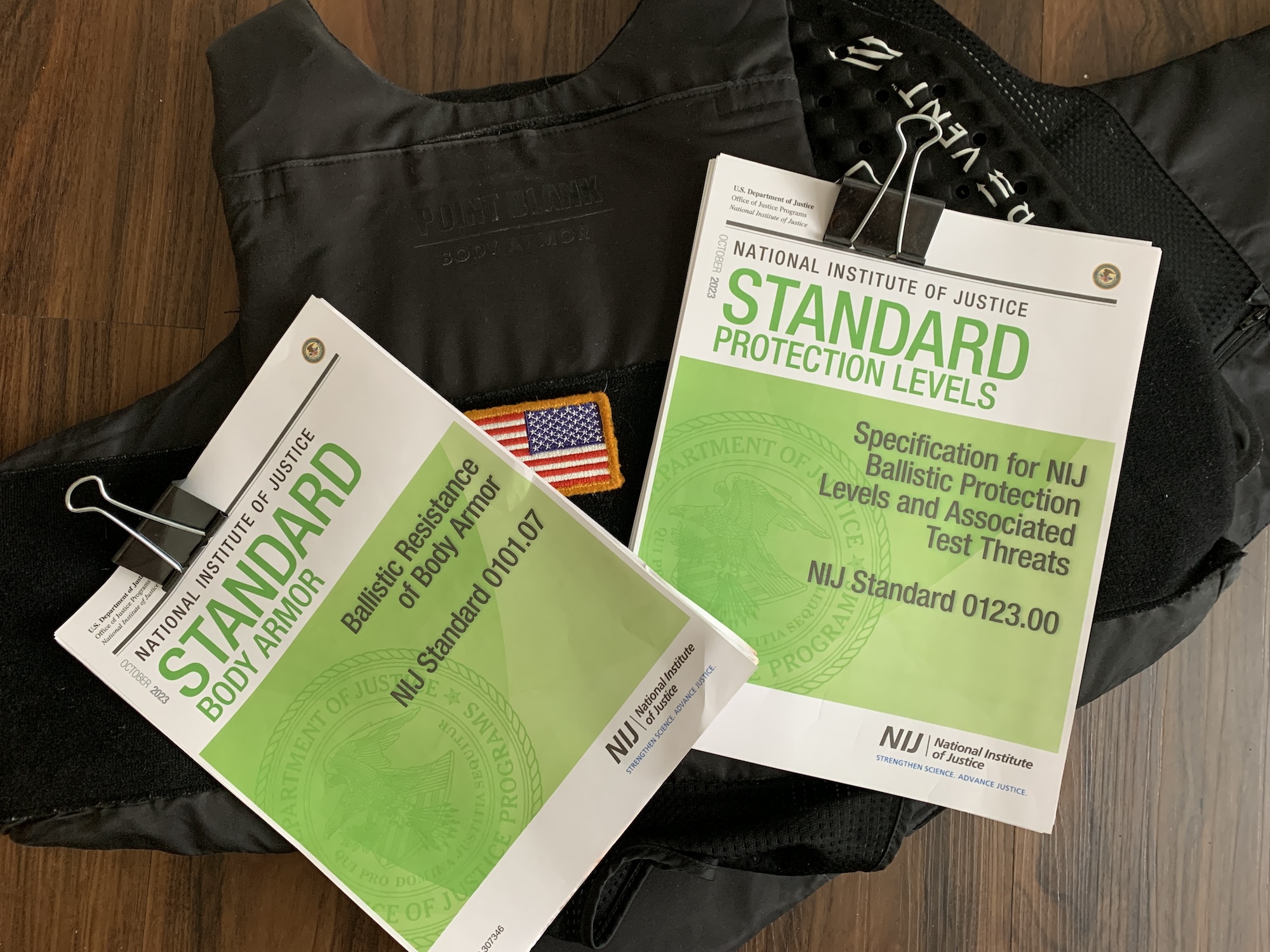

Back on November 30th, 2023, the National Institutes for Justice (NIJ) finally released two new standards for evaluating and certifying law enforcement body armor.

Originally released as a draft version for comments in January 2018, NIJ 0101.07, “Ballistic Resistance of Body Armor,” is now in print and has finally taken effect.

The companion document is NIJ 0123.00, “Specification for NIJ Ballistic Protection Levels And Associated Test Threats.” It covers which ballistic threats must be defeated and specifies the test projectiles, including weights and muzzle velocities.

Should you read it?

Yes! This is the first update standard since 0101.06 was released in 2008. And the changes in that one were largely driven by the Zylon debacle. If you wear armor, you should be educated about it. You may have to discuss its capabilities and limitations at some point in your career.

In addition to the National Institutes of Justice, several local and federal law enforcement agencies, one Department of Defense entity, and private test laboratories were involved in developing the new standards.

What’s New, What’s Changed?

NIJ has new designations for performance levels, including a new level that was previously industry-identified with nothing specific to it;

Updated test methodology for female-specific armor;

More rigorous testing of soft armor panels;

Updated test procedures for testing hard armor;

Revised back face deformation and perforation testing for all armor;

Different Levels

Previously, the levels were II and IIIA for soft armor (IIA went away in 2008), with levels III and IV for hard armor. There was a made-up III+ rating for armor designed to stop certain rifle rounds because of the different capabilities of two .223/5.56mm loads – the M193 55gr ball and the M855 62gr load.

From now on, it will be NIJ HG1 (old II) and HG2 (IIIA) for soft armor and RF1 (III), RF2, and RF3 (IV). These will cover soft and hard armor as well In Conjunction With packages that combine both.

Shotguns haven’t been forgotten, they’re covered by HG1 and HG2.

Handgun Concerns

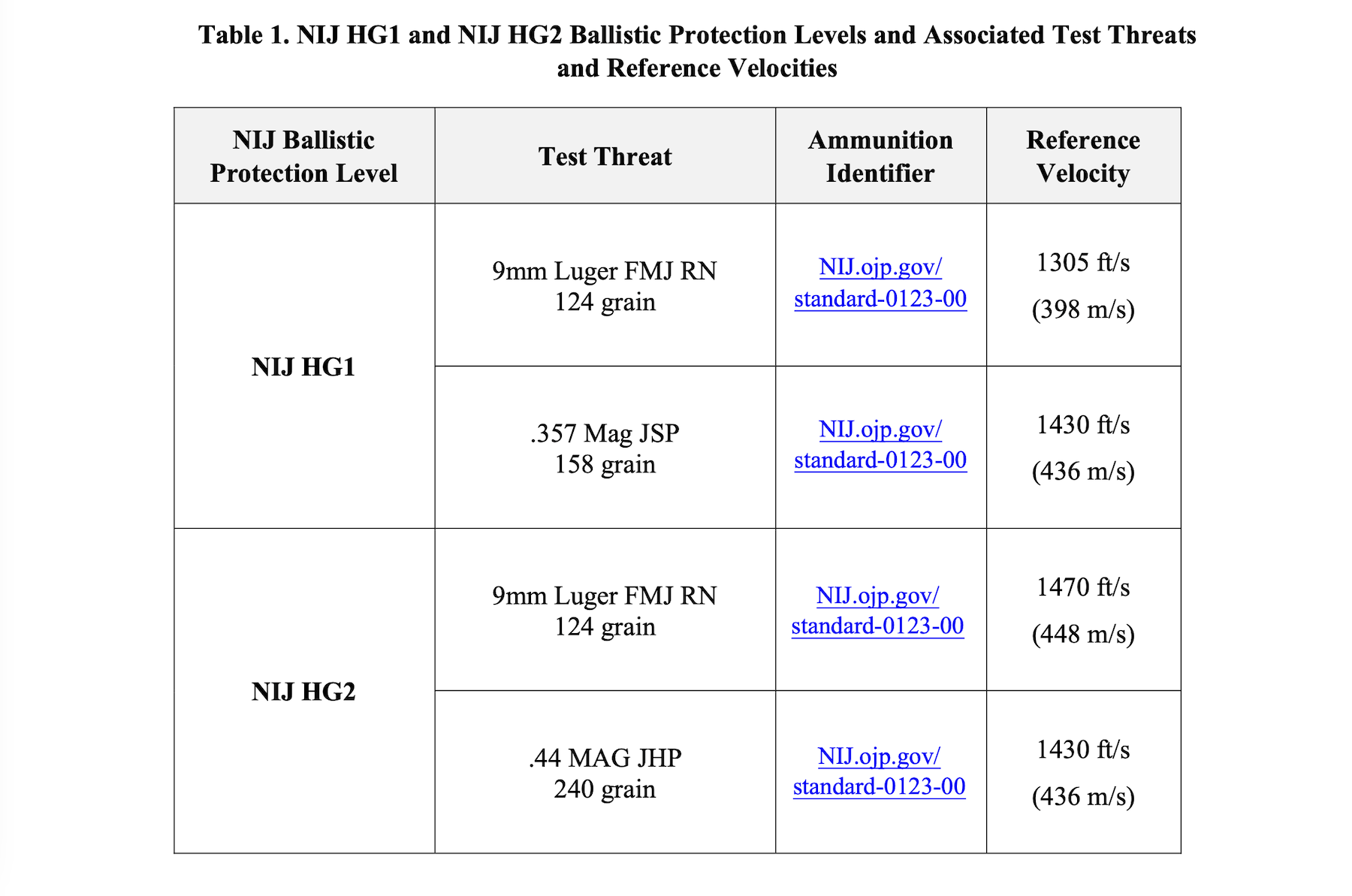

HG1 must defeat 124gr 9mm round nose full metal jacket at 1305 feet per second (fps) and 158gr .357 Magnum jacket soft point at 1430 fps. HG2 shall stop 124gr 9mm round nose full metal jacket going 1470 fps, and a 230gr .44 Magnum jacketed hollow point at 1430 fps.

Rifle Threats

Regarding rifle-rated armor, the previous standards addressed 7.62×51 NATO (.308Winchester) and an armor piercing .30-06 round. Neither level considered stopping common .223/5.56mm ammunition – 55grain M193 or 62grain SS-109 / M855 rounds. Previously, there was little understanding of the performance difference between those rounds. Some people believed that if something stopped M855, it would stop M193 and vice versa. That was a mistake.

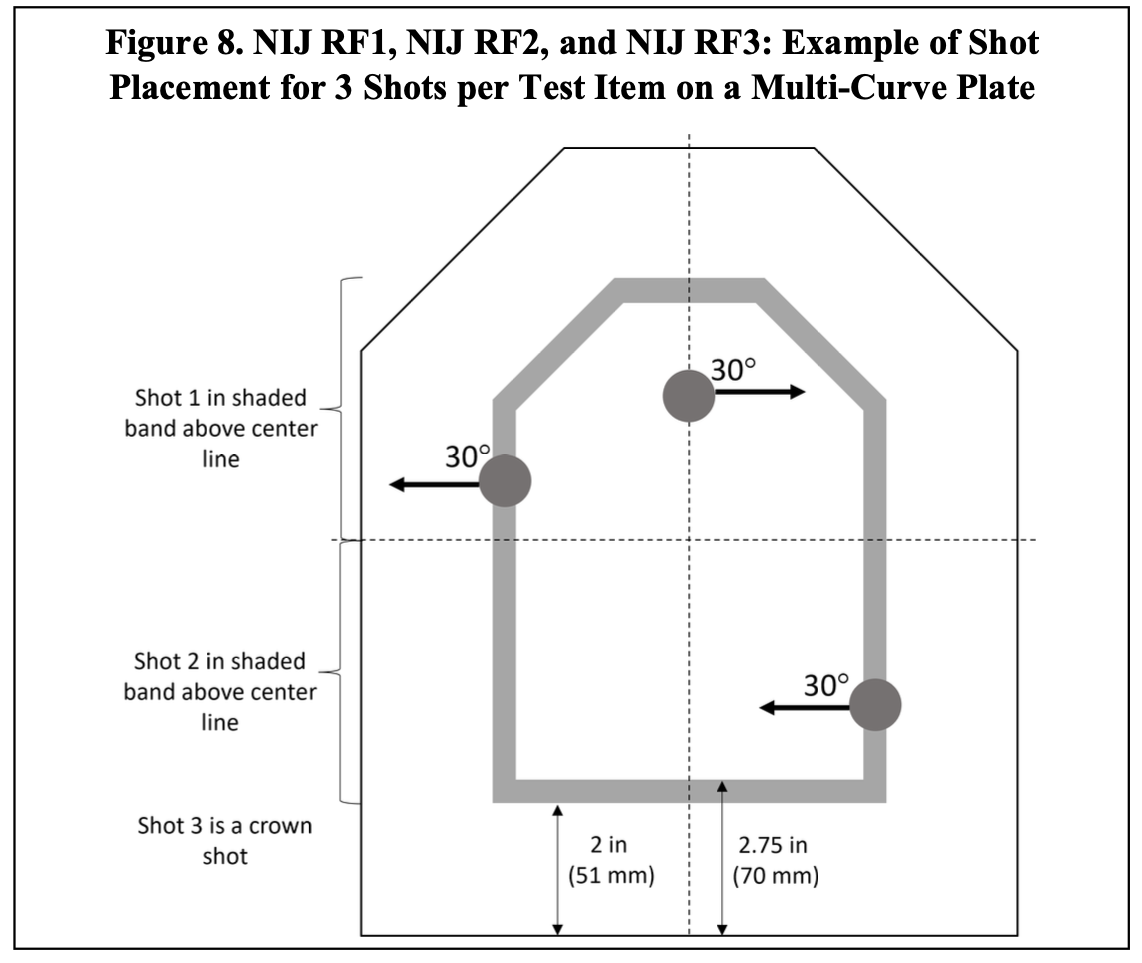

The mandated test shot locations for a rifle rated (RF1, RF2, RF3) multi-curve plate – and those shots must be angled too.

There are three rifle protection levels. NIJ RF1 needs to stop 147gr 7.62×51 M80 full metal jacket (FMJ) at 2780 fps, 123gr Type 56 7.62×39 mild softcore (MSC) at 2400 fps, and 56 gr 5.56mm M193 ball at 3250 fps. RF2 must stop all of those as well as 61.8gr 5.56mm M855 ball at 3115 fps. RF3 is only concerned with stopping a 165.7 grain M2 Armor Piercing .30-06 projectile at 2880 fps.

The projectile weights are not typos; they come from the documents.

BFD

There is concern about BFD, also known as back face deformation, causing blunt trauma injuries to the wearer. The greater the depth of the dent, the greater the likelihood of internal injury to the wearer. Now, that deformation cannot exceed 50.0 millimeters.

Any “In Conjunction With” products – plates and panels worn as a set – must be tested together.

Panels

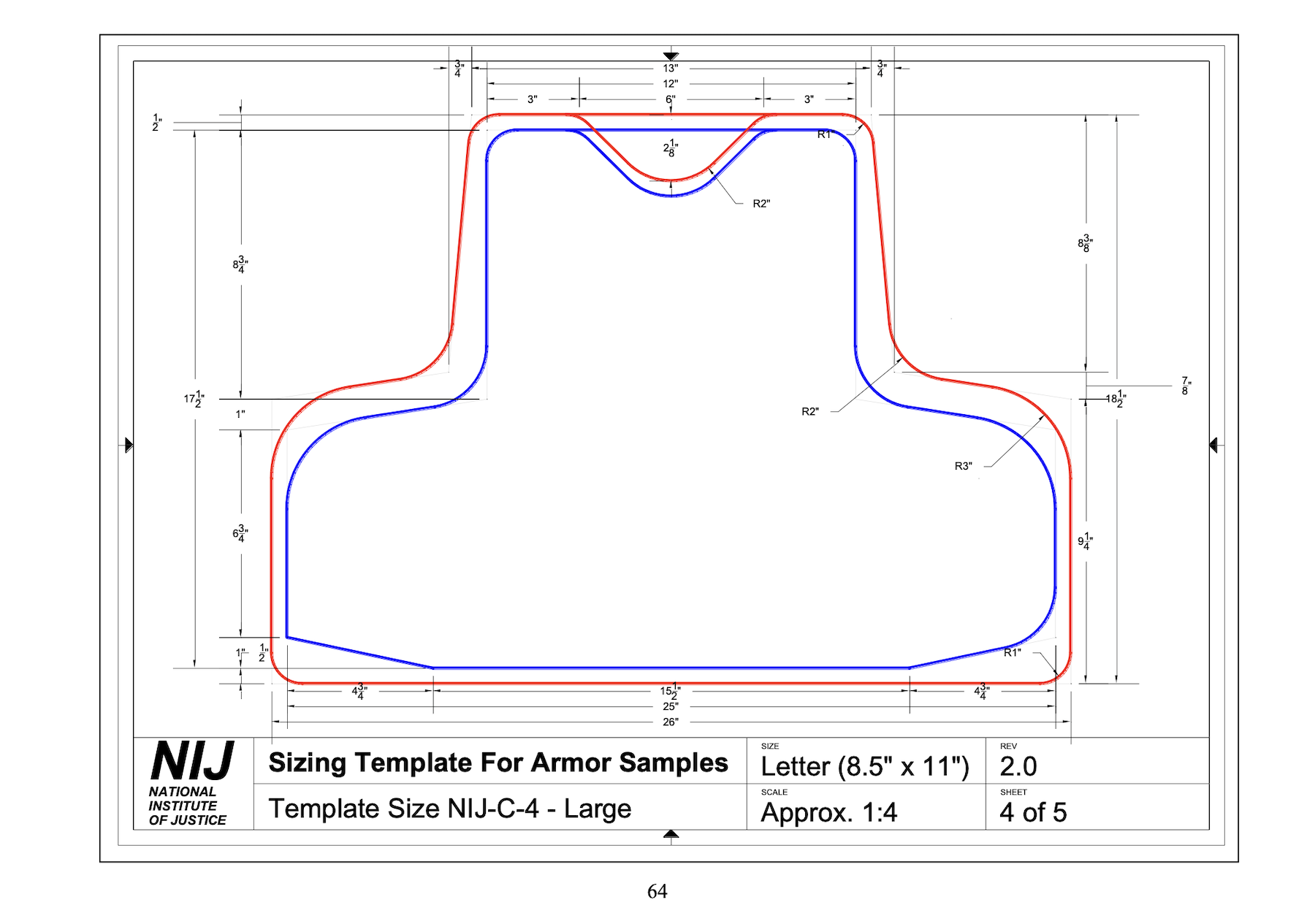

For testing soft armor panels, manufacturers must submit both small and large-size samples, with and without Neck Scoops – front and back. The standard also identifies Planar (flat, think male) and Non-Planar (with curved or darted cups, think female) panel designs. Each must individually go through the testing process.

Non-planar panels are modified to accommodate the female physique. Generally, this means cups and darts will be sewn into the panels. The document clearly identifies where the test projectiles need to be shot for the testing to be valid for repeatability purposes.

With this standard, test panels will be exposed to fluid, heat, and tumbling – before testing – to simulate environmental and wear issues.

Hard Armor

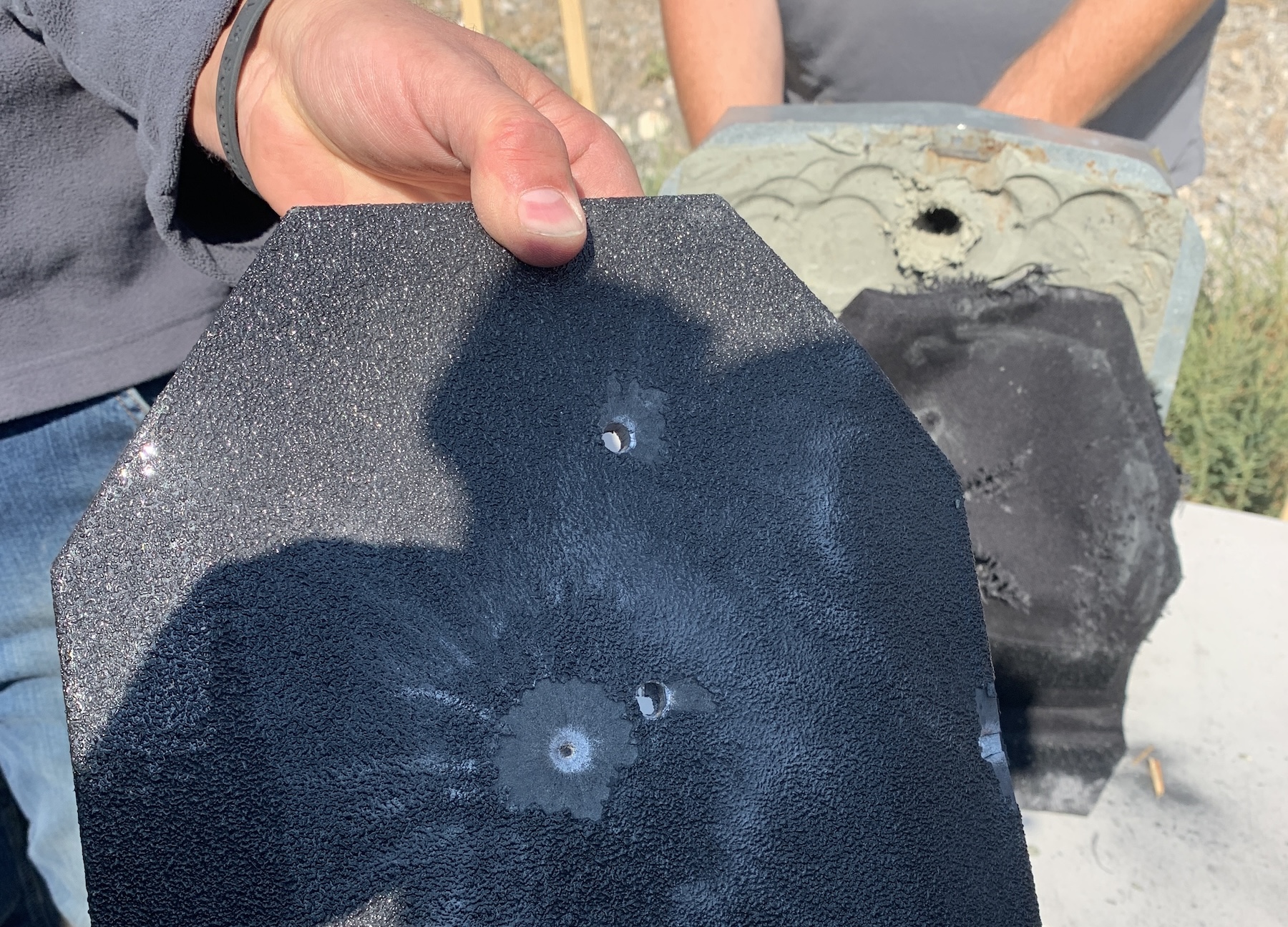

The number of test plates to be submitted and the shots required varies by rating. It can range from 10 to 83 test samples and anywhere from one to six shots per plate. None of the submitted rifle plates can be larger than 10” x 12”.

Two penetrations of a steel plate by centerfire rifle rounds at an armor demo. Notice the box with the clay in the background – and the hole in it.

During testing, the lab attaches the panel or plate to a fixture filled with calibrated clay. They can check for back-face deformation this way.

Each round is shot from a purpose-built test barrel, and the lab chronographs every one.

These documents describe controlled testing. Done to a repeatable standard by certified laboratories. That is very different from taking a sample or an old panel and shooting it.

Another View

This contact shot went right through the panel. While NIJ’s new standard doesn’t test for this, the FBI version does.

I spoke with Dr Gary Roberts, a maxio-facial surgeon who did his residency under Dr Martin Fackler – the father of modern wound ballistics. Roberts is on the faculty of Stanford University’s medical center and is a recognized subject matter expert in wound ballistics. He thought the 0101.07 standard was an improvement over the previous one; however, he thinks the FBI’s body armor standards are better. Specifically because the FBI standard tests for contact shots and uses ballistic gel as a backing material rather than clay. Roberts said he was concerned about the new RF standards not addressing current military rounds (like M993 and M995) that may be encountered domestically. The Bureau’s hard armor test involved three hits in a triangle spaced three inches apart.

Final

If this is new to you, don’t feel bad. NIJ only released these standards two months ago. While writing this, I checked several body armor websites. None mentioned the 0101.07 standard or the new threat level designations. Only one of them mentioned the 0101.06 standard, and that was in a several-year-old PowerPoint presentation.

Take a look at the standards.