feature-Keeping Training Engaging

Steel targets are an excellent tool because of their durability and ease of use. Steel targets do not require frequent replacement, conserving valuable time by training versus range setup. Despite the higher initial cost, they provide considerable savings over time.

These targets minimize the need for range supplies that paper or cardboard targets require. A simple coat of spray paint can be all that’s needed.

Modern firearms training starts with basic marksmanship before progressing to more dynamic shooting skills. Shooters then learn to balance speed and accuracy in preparation for dynamic street encounters.

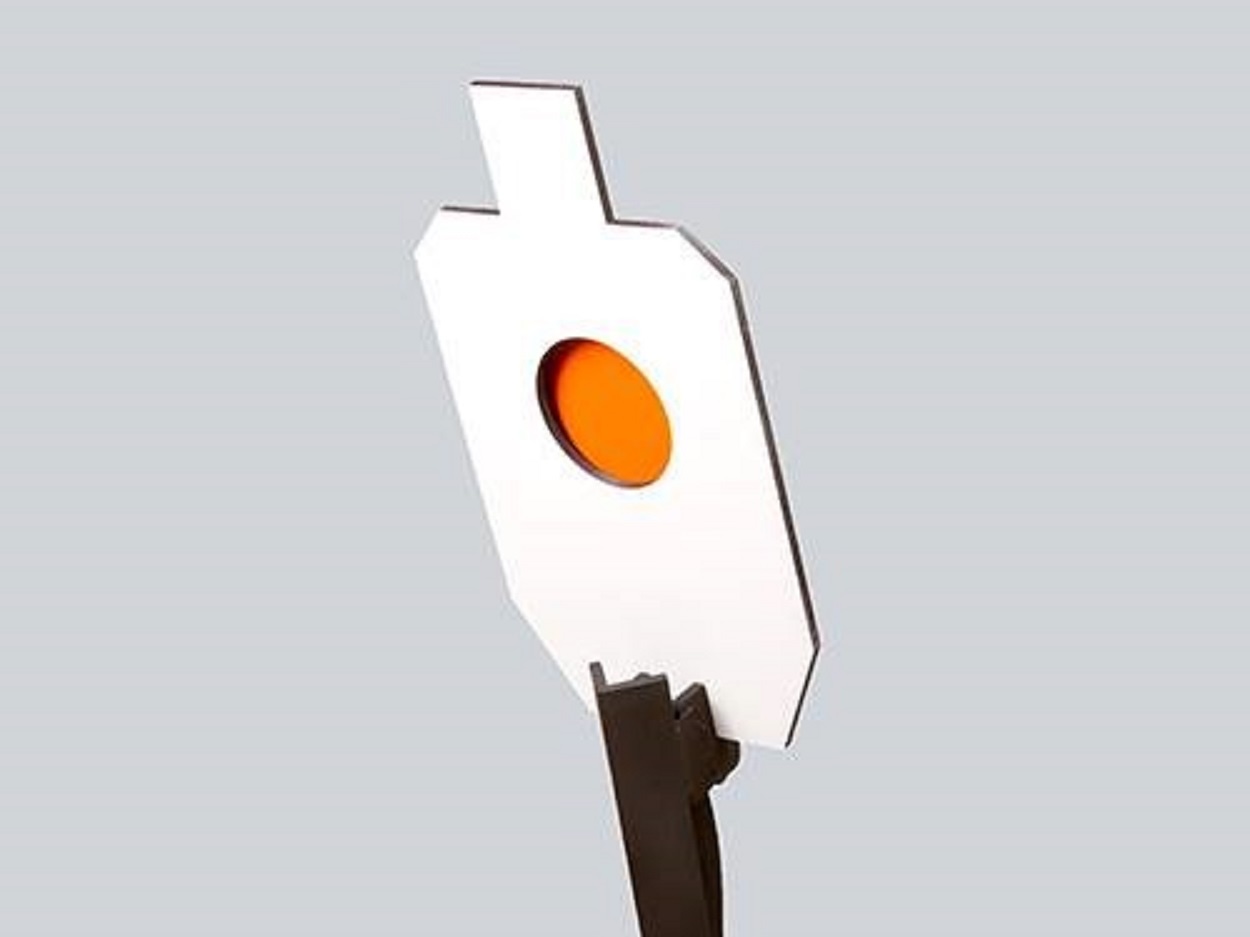

The design of the target and base system are important considerations. Modular bases and uprights allow for multiple configurations. Here are MR TARGET Hostage Targets (a 2/3 scale IPSC plate with a 6” reactive flipper) and Tall Armored Bases.

Steel targets are instrumental in developing that combination. There is immediate audible and visual feedback when hit — which shooters and instructors appreciate. This feedback helps shooters hone their shooting skills.

Then, there are safety considerations when using steel targets. Both shooters and instructors must be aware of these concerns so steel targets can be safely used.

Target Considerations

Not all steel targets are alike. The quality of hardened steel used in the manufacture of targets affects their durability and safety. Softer steel is not durable and can create a dangerous environment due to unpredictable splatter.

When purchasing steel targets, please consider these three things:

• First, look for AR500 or AR550 grade steel targets. AR550 is harder, more durable, and more expensive than AR500, but it is not always necessary. 3/8th-inch thick AR500 steel targets are acceptable for most service handguns.

• The second is the target and base component designs. The better the base design, the easier it is to use. Find out if the system is portable. Can one person set it up? Does it require tools? Is it modular?

• My third major point is who has approved what brands/designs. Many places do not allow steel targets for historical reasons. What materials are they made from? Seek training on safely using steel targets. Discuss these topics – before buying. Find a company with experience designing, building, and managing ranges – MR TARGET is a good start.

Several different re-active steel targets at MR TARGET’s manufacturing facility in Tempe, Arizona ready for delivery. They come with a lifetime warranty.

Buy your steel targets from a reputable and proven company., A local supplier may sell AR500 labeled steel that does not meet the standards required for safe operation.

For years of safe use, you need to match target specifications with their intended use. Check the manufacturers’ product guidance for the intended application. A bullet’s composition and velocity matter more than caliber when it comes to target life.

Caution

Do not use armor-piercing, green-tip, or steel-core ammunition. Bullet design plays a crucial role in bullet splatter. Frangible ammunition results in minimal bullet splatter and is ideal for training with steel targets. However, due to cost considerations, FMJ or ball ammunition is traditionally employed as a suitable alternative.

Maintaining the cleanliness of steel targets and preventing corrosion is an important aspect of steel target maintenance. A spray paint that contains a rust inhibitor would bring this target back to looking new.

Setting Up a Target Range

Choosing the right hardware is an important step. A good target requires an excellent base system. Avoid targets with mild steel, rebar, brackets, bolts, or clamps within the bullet impact zone. These can alter how the bullet breaks up on impact.

Bullet splatter is a common occurrence with steel targets. The amount of splatter depends on several factors, including angle of deflection, target condition, hardness, placement, and the design of the base and bullets.

All steel targets should be angled between 15-20 degrees. To deflect bullet fragments safely to the ground, non-reactive or static steel targets should be angled at least 20 degrees.

The target face’s forward tilt influences the angle of deflection — the more it leans forward, the larger the deflection angle. All steel targets should be angled 15-20 degrees for optimal safety. Non-reactive or static steel targets should be angled at 20 degrees to deflect fragments downward safely.

Multiple Targets

When using steel targets, you must consider several factors. Shooter and target locations are the two most important. If multiple shooters are training simultaneously, do not allow cross-shooting. On public or high-use ranges, all targets should be set up directly in front of the shooter and strongly discourage cross-shooting. Look for debris that could redirect bullet fragments toward the shooter. Positioning the steel target on dirt or grass helps maintain predictable splatter. Surfaces like gravel, asphalt, or concrete can cause splatter to hit shooters or bystanders.

There are resources available for properly educating your range staff for safe operation.

When shooting a handgun or lead shot (shotgun), keep a minimum of ten yards between the shooter and the steel target to reduce splatter and ricochet hazards. With shotgun slugs and centerfire rifle rounds, the shooters should be 100 yards from the steel targets. With high-velocity rounds (3,000 fps or more), move back to 200 yards.

Frangible ammunition or targets with a higher angle of deflection can be used safely at closer distances.

Follow the manufacturer’s guidelines and ask questions about your targets. Some manufacturers make safer and more durable targets for close-range rifle and shotgun shooting.

Minimize the likelihood of ricochet and splatter by considering where you place multiple steel targets. To avoid ricochets, do not place them parallel to each other without a barrier. When using multiple steel targets together, consider staggering them.

Target Maintenance

Even though steel targets are durable (if you follow the manufacturer’s guidelines), they will eventually need replacement. Regularly inspect the steel plate for signs of damage, such as cracking or pitting. Cratered, dimpled, pitted, or punctured steel can lead to hazardous ricochets. These are often caused by using steel that is not rated for the ammunition being used. Flat and smooth steel targets provide a predictable splatter pattern.

Preventing corrosion is crucial to steel target maintenance. One common way is to use rust-inhibiting spray paint. A few minutes of painting your targets when training is done will help preserve your investment.

Final Thoughts

Steel targets are an excellent tool for keeping shooters engaged in training and improving. They help develop both speed and accuracy. The shooters get instant feedback about their hits with less downtime resetting the range. Weather conditions have only minimal impact on them. Reach out to an experienced manufacturer before buying your steel targets for help with developing and operating your range.

RESOURCE:

MR TARGET

(480) 678-9860

MrTargetOnline.com

[email protected]

(No Ratings Yet)

(No Ratings Yet)