AC-022621-Eighty-EP-12-800

With all the media about the government trying to take out Second Amendment Rights away there has been increased interest in the eighty percent lower (EPL) receivers. The common thought behind the idea is if it is delivered without any Gun Control Act (GCA) paperwork then no one knows you have it and it would be not subject to confiscation.

While this is in theory correct, who would want to live like this? Better we as citizens fight to keep out Second Amendment Rights, but that’s another story.

As far as buying an EPL here is a paragraph from the ATF’s website on the matter:

“Receiver blanks that do not meet the definition of a “firearm” are not subject to regulation under the GCA. The ATF has long held that items such as receiver blanks, “castings” or “machined bodies” in which the fire-control cavity area is completely solid and un-machined have not reached the “stage of manufacture” which would result in the classification of a firearm per the GCA.”

There is a picture on the site that says the fire control is solid and there are no dimples on the side where the trigger pins would be bored as this would not be classified as a firearm by GCA rules and could be purchased without paperwork. They also emphasize completely solid and un-machined when describing the fire control cavity. There are some out there that have a slit machined in the trigger cavity and would not be subject to the definition “receiver blank” even though much more machining would be necessary to accommodate the trigger group. These are classified a firearm!

I would think that anyone who produces EPL’s in this fashion would be required to engrave a name and serial number, as it seems it would be classified as a firearm. If you have the blank delivered to your door without paperwork is it legal to turn it into an operational receiver?

There was some controversy over a manufacturer making blanks that the ATF did not consider blanks and they were composite material that was a different color in the trigger group category than the rest of the receiver. This would make it easier for the person to remover the trigger cavity area to fit the trigger group. The ATF’s position was the trigger cavity was manufactured, but just filled in so it was manufactured with a cavity and therefore it was a firearm. This is also where the dimpling of the trigger pins holes on the side of the receiver goes past the definition of a blank.

As a manufacturer, I like the 80% Lower (EPL) to manufacture a firearm for a customer and being blank I can label it with my company information and serial number. As a private citizen building a gun for his own use I don’t see any rules that would require it to be marked as required by a manufacturer. However, it is now considered a firearm once the cavity is machined out and any transfer from that point on would be subject to GCA regulation.

This is the regulation as imposed to manufacturers:

“Receivers that meet the definition of a “firearm” must have markings, including a serial number. See 27 CFR § 478.92 (Firearm manufacturers marking requirements).”

As with all ATF regulations a thorough investigation as to the rules pertaining to your particular purpose for the part is definitely something to consider. Hell, they could change their minds on this and interpret the whole thing differently someday. Also, a person should check his or her state and local regulations also to make sure the finished firearm is legal there.

The downside is that restricted individuals with some machining skills could gain access to and build a firearm and the ATF has some documentation of altered EPL’s found in possession of restricted individuals. There is already a law against this—collar them and throw away the key!

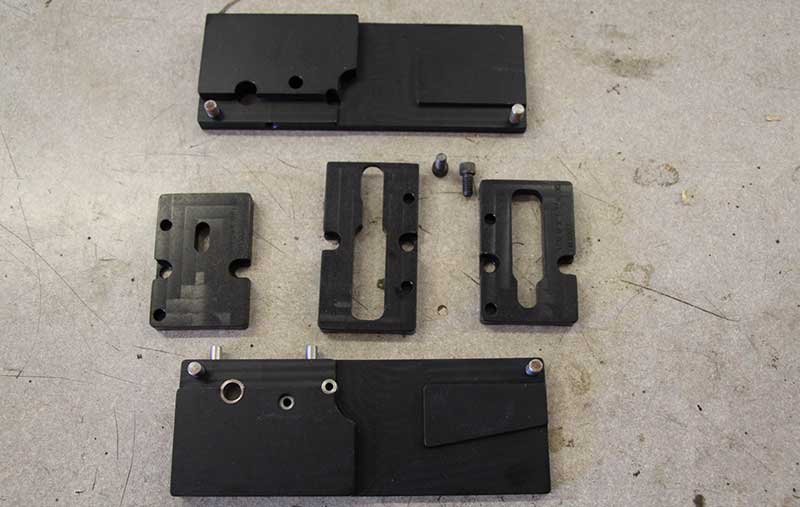

Full set of jigs from Tactical Machining. Side plates fit their EPL and the three tops for the different cuts in the cavity.

Set up in the press for the trigger pin holes and selector. Make sure the workpiece is level so the holes go through straight.

Trigger pins holes are in and lower is ready to machine out the cavity. Even without further machining it is now considered a firearm by the ATF.

First part of the cavity finished with the jig for the shelf in place. The depth for the shelf is .525”.

So the real question is how hard is it to make a functioning receiver out of one of these EPL’s? It really isn’t that difficult with some simple tools and the next question is it worth the time and aggravation in relation to cost for what you get. If you are not a restricted person you can get one to add parts to build your own version of an AR.

The .223 versions are relatively cheap, but if you decide to use a jig to help with precise placement of the pin holes and cavity it will add up to $150.00 to the cost of the receiver. Another thing to consider, a finished receiver is already anodized and finished with either black or some other color from the manufacturer. The EPLs come in the white and need a finish.

There are YouTube videos with what I call pipe wrench and hammer gunsmiths that show it can be done with little tools—and I imagine it can—but the more sophisticated the tooling the better the job will turn out. There are some well-done videos so select a good one to follow. Remember if you make a mistake most likely you will be buying another blank and the first try will be a memento on your desk.

If you are looking to build a .308 base AR you will find that they are a little more proud of them than the .223 versions and can cost up to $300.00. The EPL will have no markings on it as to the selector markings which you will have to stamp in yourself.

Some EPLs are very well thought out for the non-machinist and some require you to have some machining background. A drill press would be my bare minimum so that the part could be held more precisely. The cavity can be cleaned out with a drill bit, but I would prefer drilling pilot holes with the drill bit and finishing up with an end mill.

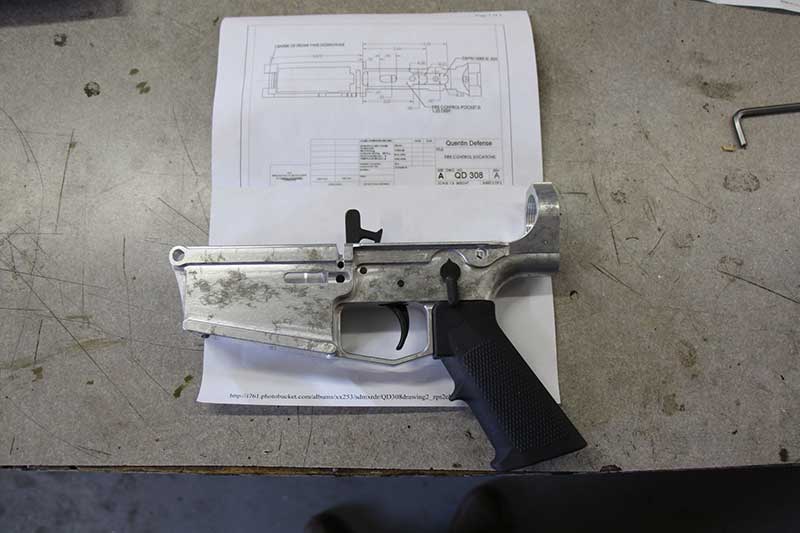

I wanted to machine out one just for the experience and started with a .308. I got the blank from Brownell’s along with the jig. The EPL and jig was made by Tactical Machining. They also carry the other tools you will need to complete the lower.

One thing I do recommend is study the parts, blank, and tooling carefully before making any cuts and between cuts. If you cut too far or in the wrong place it is seldom fixable. Most of the time in machining is setting up for the cut. The time to make the cut is very short, but once it is made it is forever.

I downloaded schematics for the receivers with dimensions for the .308 receiver.

Some of tools required are a 3/8” end mill for the fire control pocket, 5/15” end mill for the trigger slot, 3/8” endmill for the selector hole and 5/32” drill bit for the trigger and hammer holes.

The schematics that I downloaded specify that the depth of the fire control group be 1.250 inches—the same as a .223 lower but the shelf behind the safety was to be .525 inches for the .308. This is the depth that the upper will fit into. It is a good idea to have the upper when machining this to make for a tight fit.

I started by drilling out the trigger group pin holes. Then turning the jig upright I drilled some rough holes in the trigger cavity keeping inside of the jig. Using the 3/8” drill bit I drilled several holes close together to rough out as much material as possible. I figured I could bring it to the precise depth on the mill. This roughing out the cavity will make the milling easier and when the holes are at depth you can touch up the sides with the endmill. I stayed away from the edge of the jig until the last cut.

Bolt release is held in a bit differently than the .223 AR in that the pin is held in by a tiny screw. This allows the operator to adjust the tension.

rear takedown pin detent is held in by a tiny screw instead of the stock plate and is adjustable for tension.

The next step is to replace the trigger cavity jig top with the rear shelf jig. I cut it the same staying away from the edges until the last cut. The non-cutting edge of the mill will run along the jig without cutting it and when making the final bottom cut I ran it along the jig for a smooth wall at the correct size. The last cut is the trigger slot and it is started with a 5/16” drill bit and cleaned up with an endmill.

The trigger group can then be assembled as normal. If everything fits good you’re ready to go. It is a good idea to fit all the other parts into their respective spots and make sure they function before putting the finish on the lower. Some of these may require some final fitting. There is modification for the detent that holds the rear takedown pin from falling out, but it was already machined into the Tactical Machining lower and came with the parts.

Basically the detent pin was all the same as regular AR construction except instead of the spring being held in the tunnel by the stock system, subject to orbital evacuation from its home, it has a small hex head treaded plug that holds the whole detent system in the tunnel.

The other small difference is the bolt release. It is basic AR design except the lower had been formed differently the way the pin secures it. Instead of having two bumps in the receiver so a pin can be inserted and removed by tapping it out with a punch, there is a one sided threaded tunnel that a small pin is inserted for the release to swivel on. The pin is held in by another tiny threaded hex screw. These two changes are nice because the tension is adjustable with the screw. My lower needed some light fitting so the bolt release would move freely.

One very inexpensive tool that came in real handy was a magazine block that holds the lower in a vise. I was able to hold the lower in any position necessary which came in handy putting in some of the tiny screws and springs. The block fits into the magazine well and actually clicks in place just like a magazine so it won’t fall out when taking it out of the vise. Have Brownell’s throw one in when ordering your parts. It’s not absolutely necessary, but makes the job much easier. I also use mine when I am cleaning or working on ARs.

The lower is now ready to finish it up. With the EPL now containing a working trigger group it is now a firearm by ATF standards so I will stamp my company name and a serial number on it. I will also cut in some indicators for the selector and it will be ready for whatever kind of finish I want to put on it.

I like to finish with GunKote because there are a variety of colors to choose from. It will need bead blast it after all the engraving is done. GunKote requires a bead blast finish to give the coating something to purchase to and keep the coating adhered to the metal. GunKote is a baked-on coating and must be treated in an oven at 300 degrees for one hour. Brownell’s carries GunKote in spray cans for the do it yourselfer and it comes with instructions. A bead blast also gives a flat matte type finish, which I prefer.

The EPL was easy enough to finish with common tools but the mill made for more precise cuts and a cleaner finish. Whatever your reason for doing an EPL, it was a fun project and not so difficult as to require extensive machining skills. Take your time and be as precise as you can and it will be a finished gun you can hand down in the family with a special history.

I don’t think I saved much if any money doing the work, but it will be fun having a gun with my name on it and knowing I was a little more intimate with its construction.

Dave Morelli is retired from the Las Vegas Metropolitan Police Department. His duties there included being a Patrol and Field Training Officer as well as a member of the LVMPD SWAT team both as an operator and sniper.

BROWNELLS INC.

(800) 741-0015

www.brownells.com

TACTICAL MACHINING

(386) 490 – 4464

www.tacticalmachining.com